An Overview Of Our Rotating Disc Process Valves

02-28-20

Process valves are invaluable in all kinds of industrial applications, handling media, controlling components, and otherwise making equipment of all types work the way it should. Sure, process valves can be small, but they are a huge part of keeping any operations running smoothly. If a process valve fails, the results can be catastrophic. That’s why it’s so important to invest in valves that last a long time and work perfectly throughout their lifespan.

The Issues with Regular Process Valves

Typical process valves face a lot of problems and can cause a lot of issues as a result. You might find that your traditional valves leak, internally or externally. Internal leaking often happens when internal components wear out, the actuator isn’t working correctly, or the positioner is out of place. External leaking, which can cause lots of environmental and compliance issues, often happens when valves break down owing to their time in service, exposure to harsh materials, high temperatures, and vibration. You might go ahead and tighten the packing to avoid leaks, but that introduces another problem, that of sticky valves.

Ultimately, these issues lead to valves that don’t work, costing your company time and money when you have to replace valves and shut equipment down to do so.

So, what can you do about the problems typical process valves cause?

The Benefits of Everlasting Process Valves

Forget about ball valves, gate valves, globe valves and the rest. When you invest in Everlasting process valves, all of the above problems cease to exist, leaving your equipment running smoothly and working efficiently every single day.

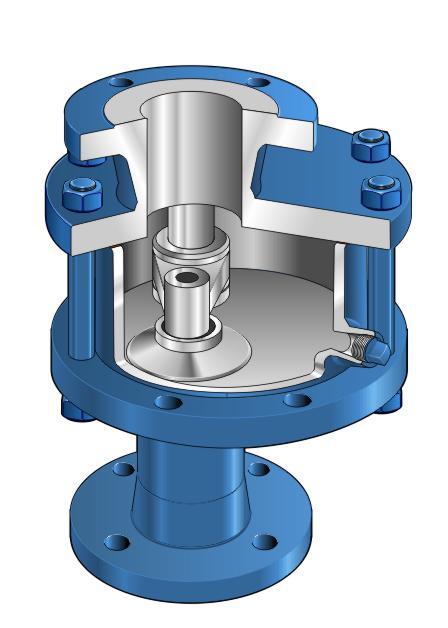

That’s because our process valves are self-lapping and rotating. An actuator moves a post and lever arm that drives the disc, ensuring the sealing surface is in contact with the seat, keeping it free from particulate. When the valve cycles, the disc rotates so it’s constantly wiping, shearing, cleaning, and polishing.

With an open-body design, solid materials have room to move out of the way so our valves won’t get stuck. Any particulate encountered, even if it’s harsh or abrasive, easily moves through the open body. Then, the rotating discs of the valve cycle through and displace unwanted materials from the seat, cleaning the valve sealing surfaces and insures a tight seal. Post-packing is self-adjusting so you can say goodbye to unwanted emissions, constant maintenance, and erosion.

Even better, our process valves are built for anything. They have been used successfully in tough conditions around the world and have endured slurry, scale, chemicals, dry solids, sludge, abrasives, and erosive materials. Everlasting process valves are in use for reactor loading, lockhoppers, vessel discharge, and other high-pressure, demanding environments.

They work perfectly down to -50F and up to 1500F. In fact, all of our process valves are ANSI class rated for handling dry abrasives and slurries up to 1500F and up to 10,000 psi. We have yet to find a condition that our process valves cannot match.

All of our process valves can be customized and configured to suit your needs. We can make these valves in most body materials, trims, or actuators. If you happen not to see what you need in our process valve brochure, it is not a problem. All of our valves are built on our self-lapping, rotating disc technology and can be custom built to your needs. Our engineering team is dedicated to finding solutions for every client. We will come on-site to understand exactly what you need in a process valve. You can count on us to develop the valves you need.

Investing In Everlasting Valves

Our valves may come at a higher capital cost than traditional process valves, but that higher price comes with a lot of product value. Consider how much money and productivity you are losing in repairing or replacing valves, even once per year. Equipment goes offline, employees have to wait, and customers are frustrated at the lack of action. Because our valves are genuinely designed to be everlasting, you will gain back your return on investment through increased uptime, reliability, and productivity.

Our team is happy to explore your options for process valves with you. You can fill in a request for quotation form online or give us a call at 908-769-0700. We are also available via email at [email protected]. We aim to have a quote back to you in one to two days for most orders.

When you are ready to buy, we make it easy with phone, fax, mail, email, and representative orders. You’re just a few steps away from reliable process valves!