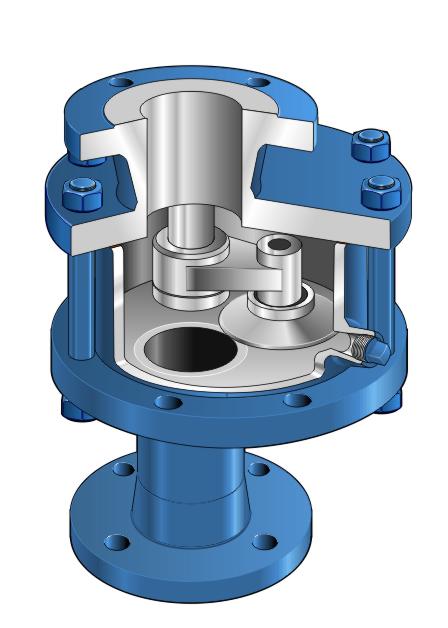

Built on our original self-lapping, rotating-disc-valve platform, our process valves feature a unique open-body design that’s self-cleaning, with seats that wear in, not out, so it achieves a tighter seal and better performance the harder it works. The rotating disc slides across the body of the valve during operation, clearing out process material and cleaning the precision-lapped surface. Post packing is live loaded for self-adjustment, reducing fugitive emissions, maintenance requirements and preventing erosion.

While many customers simply pull Everlasting Valve’s process valves off the shelf and press them into service, many others leverage our ability to extensively customize our process valves to meet your precise needs and requirements. So, if you don’t see your application mentioned above, don’t hesitate to contact us to discuss your operational requirements. Here at Everlasting Valve Company, we never stop working for our customers, and we jump at the chance to develop innovative new features and trim to support the use of our process valves in new applications.

If you’re repairing or replacing an installed ball valve more than once a year, it’s time to bring in the toughest, longest-lasting valve there is: an Everlasting valve. Don’t settle for less.