Our bulk material valve features an open-body configuration that allows particulate to move about freely, so it can be easily cleaned and expelled as the valve opens. Its unique shearing action clears the sealing surfaces and its path of particulate, forming an ever-tighter seal with exceptionally low leak rates and the assurance of a tight shut-off. Because performance improves with each disc rotation, high-cycling applications act like workout programs for our bulk-material valves—they get stronger and tougher with every repetition.

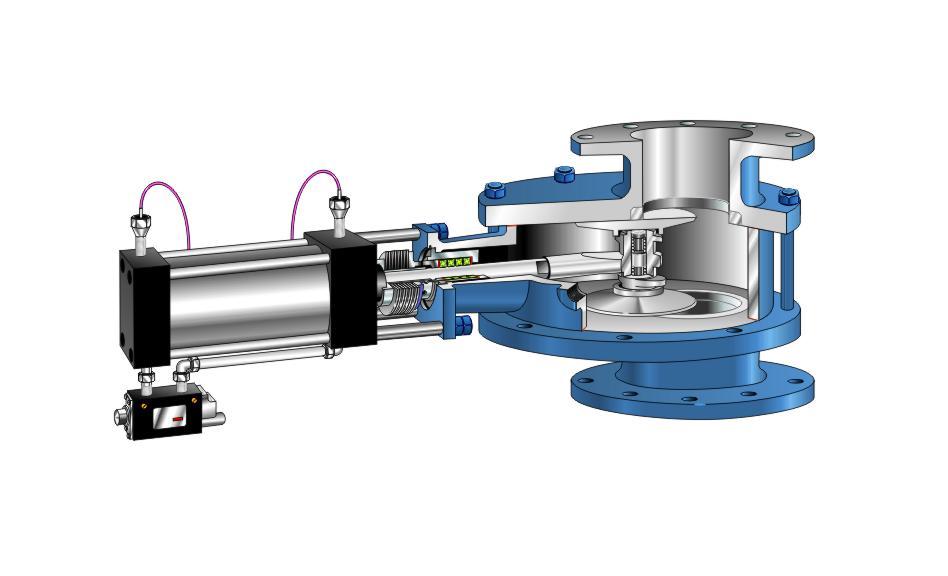

In addition, our bulk material valve’s design features a pneumatic actuator and valve that are separated—allowing for easy field packing without removing the valve from the line—and its factory-machined lapping assures a tight shut-off. It’s the easiest valve to install, use, and maintain—and it will last longer than any ball valve or gate valve on the market.

Our bulk material ’s most valuable benefit lies in its innate flexibility, as it’s designed to work in a wide variety of severe plant environments, such as in dry solids, dense and dilute-phase pneumatic conveying systems for transporter fill valve, discharge, vent and filling applications, in transfer lines, under baghouses, and in silos, cyclones, ESPs, and dust collectors.

If you’re buying or repairing your valves more than once a year—it’s time to get serious and call in the pros: our bulk material valves eat other valves for breakfast. Not only do we make your life and your fellow employees’ lives easier and less stressful, we also significantly reduce maintenance costs, boost plant efficiency, and help you avoid unplanned shutdowns. So, what are you waiting for?