Designed to handle the most abrasive media your plant can throw at them, Everlasting Valve’s diverter valves feature an innovative self-lapping, self-cleaning design that enables them to last much longer and perform better than traditional diverter valves. And because they can be switched on the fly, downtime is virtually eliminated, enabling production to continue uninterrupted for maximum efficiency. Ideal for use in conveying or pumping to multiple vessels or storage silos, our diverter valves eliminate downstream line plugging, full fringe bins, and off-quality silos, resulting in significant savings in terms of parts, labor, and production times.

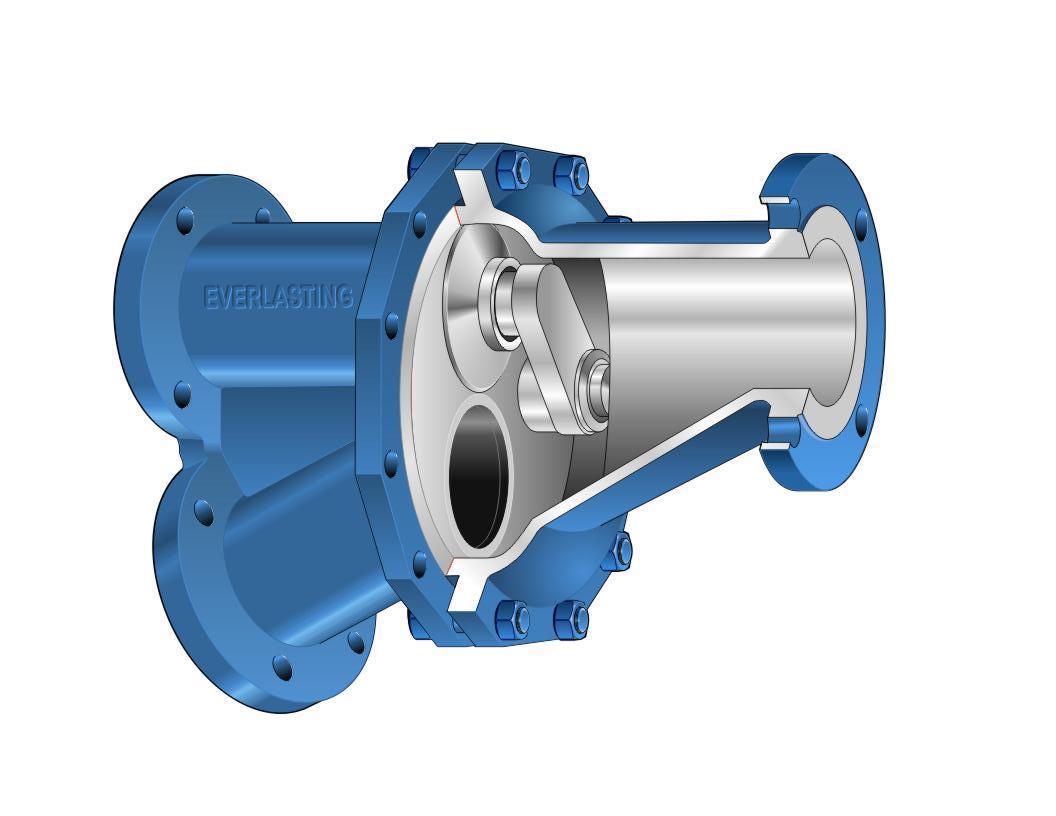

For applications rife with erosive slurry and abrasive solids, Everlasting Valves keep going long after other valves have become unseated or clogged with sludge or have failed to seal properly. With a unique open-body design, our diverter valve offers plenty of room for media to flow freely and discharge cleanly while the closed seat and disc surfaces remain sealed off from abrasive particulate. As the self-lapping disc rotates, it polishes away any scratches that develop and forms a seal that becomes tighter and stronger the more it’s used.

With Everlasting Valve’s diverter valves, your plant can keep going with no downtime between planned shutdowns. Contact us today to learn more and tell us about your toughest operational challenges.