What Is The Best Slurry Control Valve?

03-24-21

In an industrial setting, controlling the flow of clean fluids is a simple affair. But once solids become part of the flow, things get more challenging. A valve meant for straight liquid clogs, deteriorates, and slows down work quickly once it encounters a slurry.

If you need to control slurry flow, you need valves made for the purpose so you aren’t having to frequently replace them and lose productivity. Whether abrasives in oil sands or acids in chemical plants, slurry can give your equipment a beating.

The right slurry control valve can mean more uptime and increased production at your plant. They can be complex enough to adjust automatically to pressure and temperature changes or simple enough to just start and stop the flow.

So how to choose and just what makes for the best one? Here’s a look at industrial control valves for slurry and some tips for picking ones for your production line.

The Rough and Tough of Slurries

Slurry can be tough to move along, especially when it’s abrasive, corrosive, or features a high percentage of solids. It can damage your industrial flow control valve in at least two ways:

- Material collects and hardens in the pockets or cavities of the valve structure

- Restricted flow increases velocity, which means more abrasive wear on surfaces

Your best choice for a slurry control valve is going to use materials that improve durability in the face of harsh slurries. They need to be able to withstand the abrasiveness, which leads to using harder internal materials like ceramics or metal.

Types of Control Valves

You have a lot of choices when it comes to slurry control valves thanks to different materials and operations. An ideal choice would be something that can clean itself and breaks apart scale during operations. The best valve types also have no void spaces, cracks, or cavities where the suspended solids can collect.

Gate Valves

You’ll see these used mostly for on and off service, especially in straight-line systems that have minimal restriction requirements. They don’t work well for most slurries and thick liquids, though. Too much vibration and the slow response times for opening and closing serve as the biggest drawbacks to using them.

Globe Valves

These linear motion valves are used to start, stop, and regulate flows. The value uses a plug that is lowered into the center of the valve. Open the valve and the plug raises to let fluid through.

It works well as a general-purpose valve for high temperatures, but you’ll find it wears quickly when you have to leave it in a partially open position very much.

Diaphragm Valves

These are great for throttling, especially with corrosive liquids and low temperatures and pressures. They provide a leak-proof seal to ensure a tight shut-off and are easy to clean and maintain.

Pinch Valves

You find these often in the mining industry, but they’re also common in chemical and wastewater plants. They work well in most applications and are inexpensive to install. If you have a slurry with a significant percentage of solids, pinch valves can be a good choice.

These seal using flexible elements like rubber tubes, which are pinched to control fluid flow. The rubber is the only part of the valve touched by the slurry.

Rotating Disc Valves

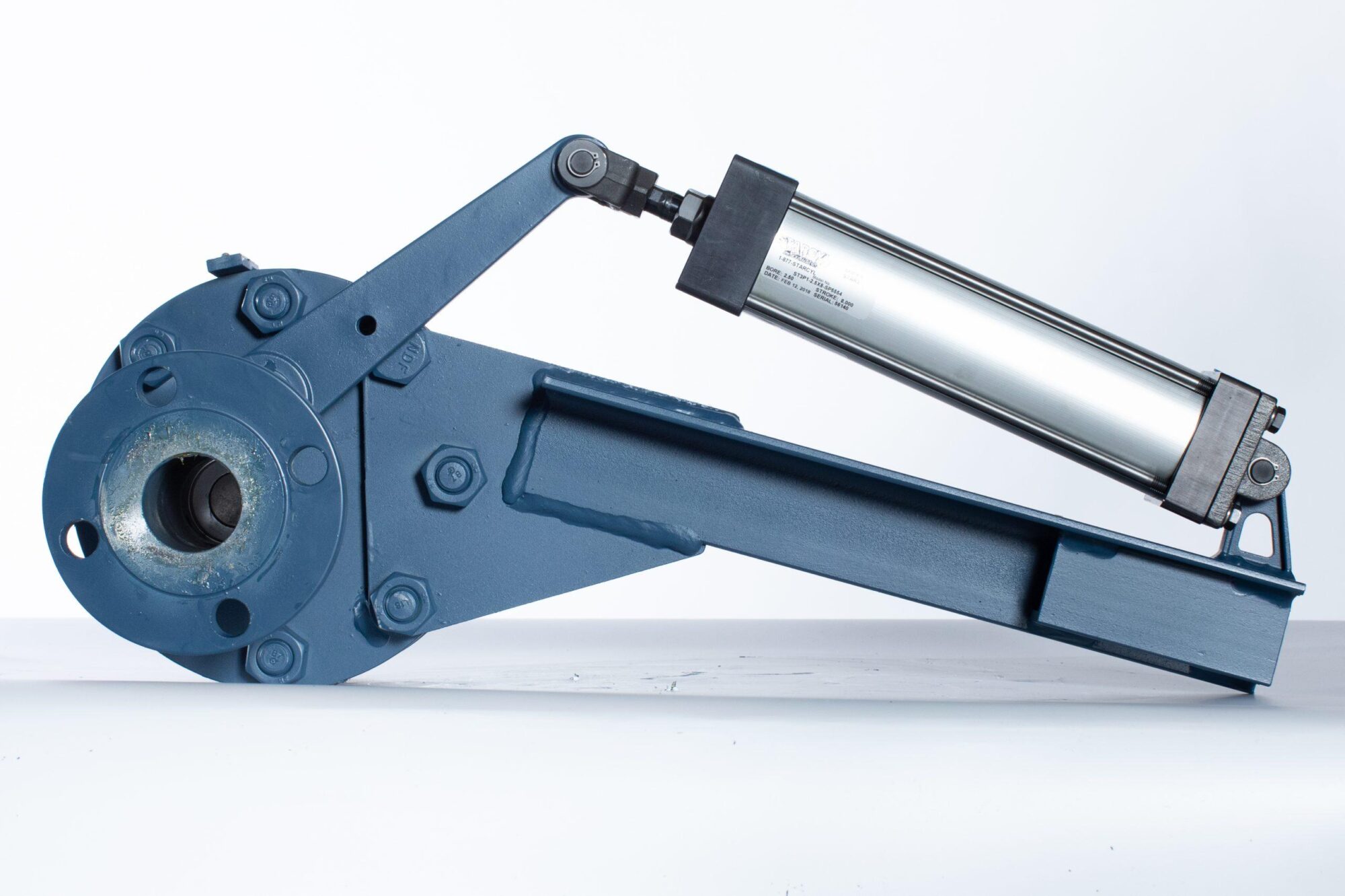

We use rotating discs for our valves in an open-body design that can handle any type of material. The self-lapping discs clear away residual material to keep the valve clean. The more you use the valve, the better the seal gets.

This type of valve can replace any of the standard configurations like globe or butterfly valves and be customized to your needs. Our hydraulic flow control valve is designed to eliminate leaks even under high pressures.

What to Look For

So what makes for the best one? A lot depends on how you plan to use the valve. The kind of slurry you deal with should be your primary concern and not costs.

If you’re working with slurries at low temperatures and pressures, a diaphragm or pinch valve is often used, and Everlasting valves are often used here as well. But heavy-duty slurries need more specialized valves to manage the flow properly.

Important considerations for slurry applications include the wear caused by the abrasion or corrosion of the slurry itself, which dictates the materials you want the valve made of. The amount of friction might influence a choice of metal or rubber materials, while a valve that needs to close under pressure needs to be made of harder materials.

Characteristics of your slurry are key deciding factors in choosing the right valve. These include:

- Percentage of solids

- Particle size

- Flow rate

- Temperature and pressure

- Composition

If these factors direct you to look for a tougher valve, you should start by considering the materials it is made of, especially if you’re working with highly abrasive or corrosive slurries. The material choice impacts the sleeve, seat, body, and housing of the valve.

Carbon or stainless steel can mean additional costs when you purchase the valve but reduces costs later in terms of premature replacement, repair, and downtime. We use it for our valves because it tops out other metals, plastics, and even ceramics for durability.

Choose Your Slurry Control Valve

Certain valves work well when you have corrosive or abrasive slurries to contend with. You want to carefully consider the selection of a slurry control valve as the right choice can mean cost savings over time. Quality control valves for slurry service can last for years before needing repair rather than months.

Investing in durable process valves keeps your operation running smoothly. The Everlasting Valve design creates a nearly indestructible flow control valve you can rely on. Contact us to talk about how our stock or custom valves can give you long-lasting service.