What Exactly Are Double Dump Valves?

06-09-25

In industrial applications where rapid material discharge and precise flow control are critical, double dump valves represent a sophisticated solution that addresses the limitations of traditional single-outlet systems. These specialized valves have become increasingly essential across industries dealing with bulk materials, powders, and granular substances that require controlled, efficient discharge processes.

Understanding Double Dump Valve Fundamentals

Double dump valves are engineered with two separate discharge outlets, allowing operators to direct material flow to different destinations or achieve more controlled discharge rates. Unlike conventional single-outlet valves, this dual-port design provides enhanced operational flexibility and improved process efficiency. The valve body typically features a Y-shaped or dual-branch configuration, with each outlet equipped with independent control mechanisms.

The primary advantage of double dump valves lies in their ability to manage material flow with greater precision while reducing system downtime. When one outlet requires maintenance or experiences blockage, the alternate discharge path ensures continued operation, making these valves particularly valuable in continuous production environments.

Key Applications and Industry Uses

Manufacturing facilities across multiple sectors rely on double dump valves for their material handling operations. In the cement industry, these valves facilitate the controlled discharge of cement powder from storage silos to different packaging lines or transport vehicles simultaneously. Chemical processing plants utilize double dump valves to manage the flow of various powdered chemicals while maintaining strict contamination control between different product streams.

Food processing operations benefit significantly from double dump valves when handling flour, sugar, and other bulk ingredients. The dual-outlet design allows for simultaneous filling of different processing lines or packaging systems, improving overall production efficiency. Pharmaceutical manufacturing also relies on these valves for precise control of active pharmaceutical ingredients and excipients during tablet and capsule production processes.

Mining operations frequently employ double dump valves in ore processing facilities, where controlled discharge of crushed materials to different processing stages is essential for optimal mineral recovery. The robust construction of these valves makes them suitable for handling abrasive materials common in mining applications.

Design Features and Construction

Modern double dump valves incorporate several critical design elements that ensure reliable performance in demanding industrial environments. The valve body is typically constructed from high-grade stainless steel, carbon steel, or specialized alloys depending on the application requirements and material compatibility needs.

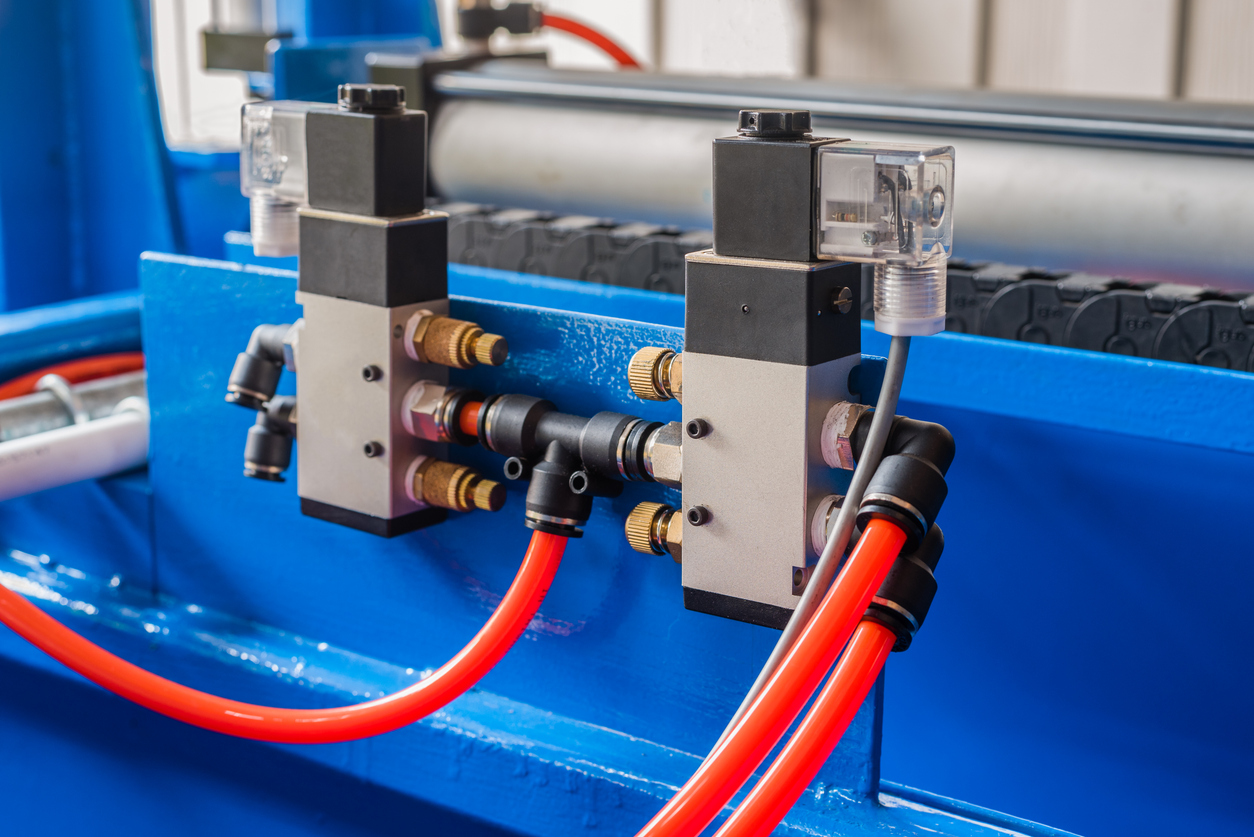

Sealing mechanisms in double dump valves often feature elastomeric or metal-to-metal seals, with the choice depending on temperature, pressure, and chemical compatibility requirements. Advanced designs may incorporate pneumatic or electric actuators for automated operation, allowing for remote control and integration with plant control systems.

The internal flow path geometry of double dump valves is engineered to minimize material buildup and prevent bridging of cohesive materials. Smooth internal surfaces and optimized discharge angles help ensure consistent material flow while reducing wear on valve components.

Operational Benefits and Advantages

Double dump valves offer several operational advantages that justify their implementation in industrial material handling systems. The dual-outlet configuration provides redundancy that enhances system reliability and reduces unplanned downtime. This redundancy is particularly valuable in critical production processes where material flow interruption can result in significant economic losses.

Process efficiency improvements are another significant benefit of double dump valves. The ability to discharge materials to multiple destinations simultaneously can increase throughput while reducing the need for additional handling equipment. This efficiency gain often translates to reduced labor costs and improved overall equipment effectiveness.

Maintenance advantages of double dump valves include the ability to service one outlet while maintaining operation through the alternate discharge path. This capability is especially valuable in continuous production environments where scheduled maintenance windows are limited.

Selection Criteria and Considerations

Proper selection of double dump valves requires careful consideration of several factors. Material characteristics, including particle size, density, flow properties, and chemical compatibility, directly influence valve design requirements. Abrasive materials may require specialized wear-resistant coatings or hardened components to ensure acceptable service life.

Operating conditions such as temperature, pressure, and environmental factors must be evaluated when specifying double dump valves. High-temperature applications may require special materials or cooling systems, while corrosive environments necessitate appropriate material selection and protective coatings.

Flow rate requirements and discharge patterns also influence valve selection. Some applications may require equal flow distribution between outlets, while others may need variable flow control to each discharge point.

Installation and Maintenance Best Practices

Successful implementation of double dump valves requires proper installation and ongoing maintenance protocols. Installation should include adequate support structures to handle the valve weight and dynamic loads during operation. Proper alignment of discharge outlets with receiving equipment is essential for optimal performance and reduced wear.

Regular maintenance of double dump valves should include inspection of sealing surfaces, actuator operation, and internal wear components. Establishing preventive maintenance schedules based on operating conditions and material characteristics helps ensure reliable long-term performance.

Future Developments and Innovations

The evolution of double dump valves continues with advances in materials technology, automation integration, and smart monitoring capabilities. Modern valve designs increasingly incorporate sensors for monitoring flow rates, valve position, and component condition, enabling predictive maintenance strategies and improved process control.

Contact Everlasting Valve today to discuss your project requirements.